Keith Wayland: Good morning everyone. My name is Keith Wayland, managing partner with RPI Consultants. I want to thank you for taking the time to attend this morning’s webinar on Par Management Best Practices. This presentation was originally delivered at the request of the Keystone User Group earlier this year. I’m very excited to be able to assemble the group that delivered it. Mr. Jason Kwasnik, Ms. Stephanie Kowal, Mr. Dan Farruggio to deliver it via webinar. Great presentation today and I am going to hand off to them in just a second.

First I have a couple of housekeeping notes. Number one, this webinar is being recorded and it will take us a week or so to get it edited and loaded up to YouTube and hopefully it will be there for reviewing. Number two, please do take advantage of the fact that our presenters are here and this is interactive and you can ask questions through the go-to webinar chat or questions modules. When we did this in … At the Keystone there was a lot of interaction that was super helpful so please if you have comments, suggestions, questions just throw them out there and without further ado I will hand it off to our presenters.

Jason Kwasnik: Thank you, we are here for pumpkin chunkin … Par management best practices and about us. We were formed in 1999, now we are a total of sixty plus nationwide consultants around the country. We do a lot of presentations and this is of course our team pictures and our … Three of us aboard. Now our agenda. First we are going to be talking about Par setup in Lawson. Then we will be going on to managing Par levels, the integration of Pars with MSCM, reporting, and some best practices. Following the end of that, we will be doing our Q and A. Now the item location versus par location. When you think of par locations … Par locations also besides adding an IC12 builds IC02 ship-to-location for your non-stocks, builds an RQ04 for your internal delivery addresses for your delivery packages and for your stock items. But when you build out your IC81 it builds an IC12 record in the background. Now you have to realize that all modifications are done through IC81 not through IC12. It is just a record that is viewable but not editable.

Stephanie Kowal: As Jason mentioned, IC81 creates that RQ01 automatically so you have to remember as part of your setup and maintenance to go back into that record and add that account unit so you are able to process requisitions. There is also some ongoing maintenance that needs to happen to make sure that you are monitoring this setup from your end users. So when they are adding a vendor source sometimes it could not match the vendor that you are actually … Have a vendor agreement for, a contract for.

It is definitely helpful to build some sort of report to help compare the two and make sure you are staying on track. Another area to take into consideration is the unit of measure that is built and whether or not that is the unit of measure on the agreements so changing your default issue on IC11 can really help with that procure to pay process. There is also some MSCM errors that can hold up your requisition in RQ10, so if you have a request for ten items lets say and one of those items has an error that error will stay in MSCM, it creates an unrealized requisition in RQ10 which you then need to go view and release on your own.

We have worked with some end users that have actually built a process flow that will look for those errors and then automatically release that requisition but in the meantime just make sure you are monitoring those unreleased requisitions and you can pull from the source. It will say that it came from IC83. You can look for all requisitions that are unreleased that come from IC83 and make sure that they are being monitored.

Jason Kwasnik: Stop me if I am wrong but I do believe the newest version of Mobile Supply Chain will create the requisition and release it but create a separate record for the error?

Stephanie Kowal: I haven’t heard that but that would be great news.

Dan Farruggio: Yeah, I haven’t seen that either but that would be awesome if it were.

Jason Kwasnik: I heard that somewhere and just wanted … And not sure what version.

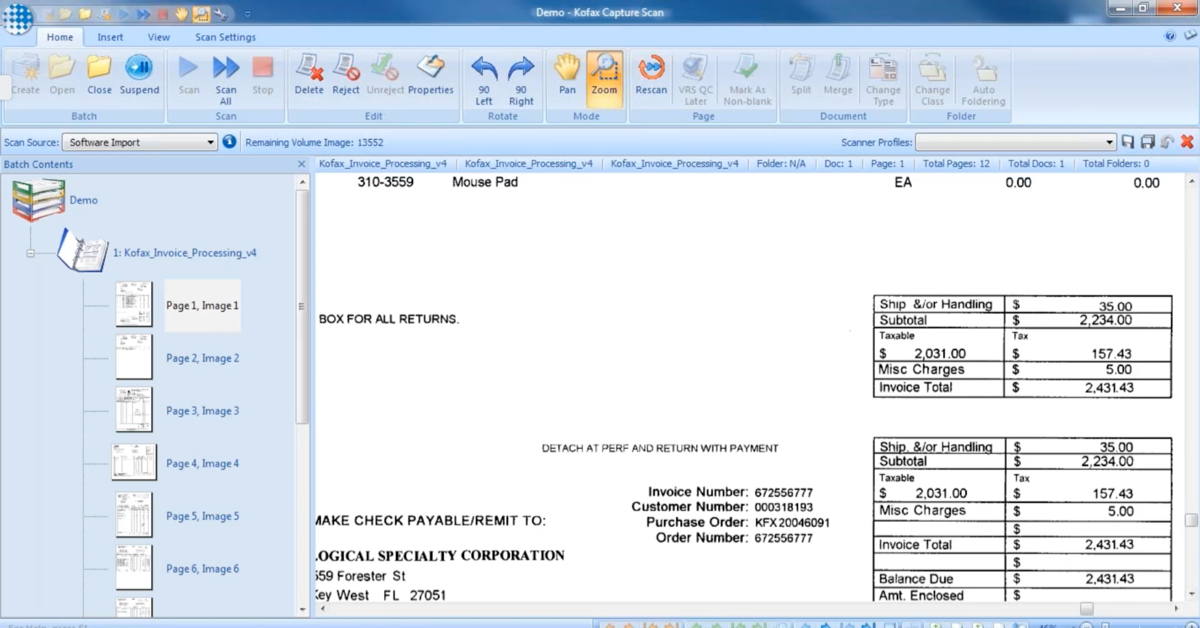

Stephanie Kowal: I’ll have to check that out. There is also unreleased agreements can cause some issues with requests going through as well, so making sure that you are monitoring when changes are made to those agreements, that they are being released. Here is this example of a custom report created with Crystal that was posted to LBI dashboard to help monitor them. It shows how IC81 was setup and who the default PO13 vendor is.

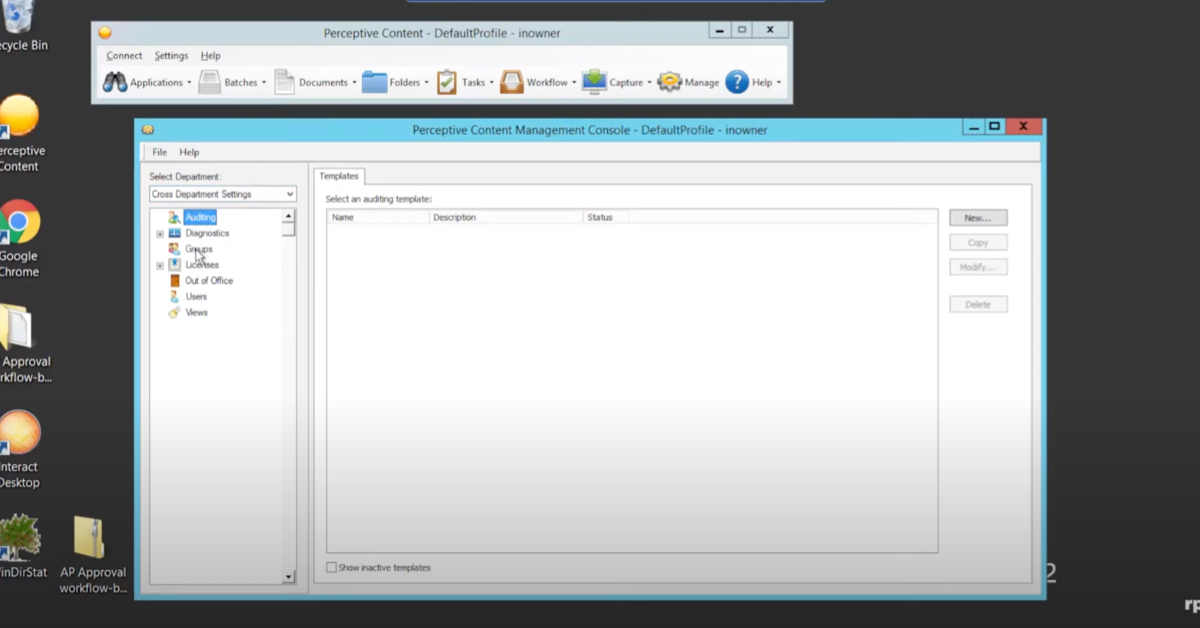

Managing par levels. IC03 is a really really helpful screen to utilize. This is report groups. Most likely you have multiple par locations for one account unit so you can utilize IC03 to build all of those pars in a group and then a lot of the Lawson reports you can run by report group. That will help speed up the process. Here in this table are some canned reports from Lawson and increase screens that can be really helpful to utilize but also do not forget that you can pull directly from the tables in Lawson to get some additional information and build some custom reports. Item location, item source, PO line, IC trans, your shipment details, invoice details, and also IC audit. If you have auditing turned on in IC01 this can be really helpful to build some KPIs, do some troubleshooting if you have had a system issue.

Here we have some examples of some reports that have been created. This is going through par analysis and giving you some recommendations if the par should be upped, decreased, or removed from the par cart. Here is one that is a little bit more complex showing the same similar type of information and my favorite, is this one that was created for item change report. Often times what can happen is … Why isn’t it showing up here? Do we have a freeze with our TV? Often times what can happen is your MMIS team is continually updating records. You could have gotten an order exception from the vendor, unit of measure change, description change, and it is very difficult to communication that to your end users at times. You may have had a process where you were manually keeping track of all of these but your materials team really needs to make sure that those labels are updated in the areas depending on what change has been made.

This report displays any item and it is run by … This one here was run by an actual par and will let them know any time a description either one or two par level bin unit of measure or manufacture detail has been changed. Here it will let them know to update the label. If they recently added it to their par cart or the MIS team may have made a replacement if you had a conversion, it will let you know to add a label and if it has been removed it will let them know to remove the label. Really really excited about this one if you utilize Crystal Reports just reach out to us, I’ll be happy to share it with you.

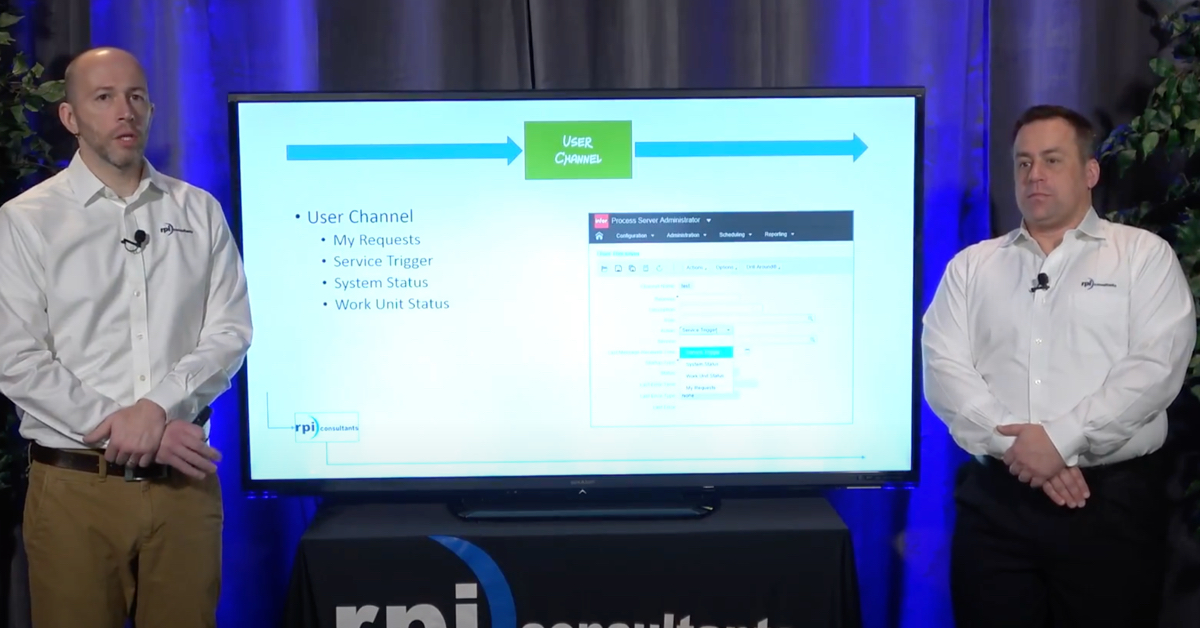

Dan Farruggio: Now we going to talk a little about managing your MSCM configuration to optimize some of your par management. The first thing you need to know about setting up MSCM is you need to have a Lawson security group. It is required. That group is defined in your filter … Your MSCM configuration.properties file and that group needs to be created in your RM security administrator and assigned to users coming over to Mobile Supply Chain. Without that group assigned to the users, they will not show up in Mobile Supply Chain.

There are two levels of administration you can think of it. The first one is … You have your IT administrator. They are responsible for the initial install, for looking at any kind of logs, trouble shooting any errors, and then you have your day-to-day administration which is typically a materials management super user. Their typical responsibilities would be managing groups, editing … Adding roles to groups. Assigning users to different groups, location management, things that would affect an end user’s ability to perform certain tasks in Mobile Supply Chain.

You do have the ability to add a user directly from portal. If they are in that Lawson security group or you can add them independently directly from Mobile Supply Chain. They don’t need to be a Lawson user to have Mobile Supply Chain access.

Another good thing to know is Mobile Supply Chain … Will request their setup. Within the MSCM application you assign … You can assign global access to a user or specific access to specific locations, if it is by company or individual locations.

Some good stuff to know about Mobile Supply Chain is you have the ability to set a max order quantity. You could order twice par, three times par, if you know … If you have a skeleton crew on the weekends you order out on a Thursday or Friday to make sure you have sufficient supplies on hand before going into the weekend. You set that up in the par configuration screen of Mobile Supply Chain.

Another option in MSCM is to show the quantity on order. You can see in the little screenshot of the handheld coming up on the next slide … It’s up there … that if you have a vendor source on IC81.2 and you have … item amount order, it will show up in that little QAO box. It is good to know so you don’t have duplicate orders sitting out there.

Another really helpful function of Mobile Supply Chain is to utilize the my par forms. When a user logs into the handheld’s account par forms it shows the pars that are ready for them to count. It is specific to that user so they can select all of them and download them if they count them on a daily basis. They will also have the ability to back out of that screen and select all the pars as well. If they are covering for another employee that is out, they do have the ability to select other par forms rather than the ones that are under my par forms.

A big point of discussion, especially for new implementations of Mobile Supply Chain is labels. Sounds very simple but is actually … They are very beneficial to have and a lot of detail and thought goes into them. If you want to have color coded labels, if you want to use the out of the box Mobile Supply Chain provided labels. If you do use the out of the box labels you will need a zebra printer. That label looks like the blue one up top. That is your standard out of the box. You are able to customize these labels but you can … The customization only really allows you to change the order of the fields. I don’t believe you can really add fields to the customization screens without going in and customizing the ZPL zebra printer language.

There’s other options out there. You could use a … You could build your own database in Excel or Access and if you have a bar-coding font which is code three of nine or 128A, you could create your own standard labels and a variety of labels so it is easier to roll out different styles of labels to different departments and there is also other software … Third party software out there that costs as little as thirty dollars to implement on your local desktop and build a label database that way. A lot of folks like to get down and customize labels to meet their needs and requirements and show the data they think is most important to them.

A little about par counting reports. In these reports … It’s always best practice to go in at least once a day to make sure all of your par counts have been submitted without errors. Like Stephanie was saying earlier sometimes you have one error on a par count and it might hold up an entire requisition. These par counting reports are what shows you what made it through and what didn’t make it through.

Some common errors that you see are the requester ID is not valid and that just means that you have some kind of mismatch between your IQ04 record and the requester identity that is setup in security.

Unit costs. Unit costs required … That’s really a big error that you see pretty frequently for new implementations. If you don’t have a PO25 record or it hasn’t been ordered or received yet or you add a new item to your location or to your item master and it doesn’t have a cost associated to that item. That will require you to go to RQ10 and enter cost for that item the first time around. The good news is that once unit cost is entered you never have to worry about it again for that particular item.

Another common error that you see is authentication failed on user. That just requires … It comes up with a password reset. If I’m logged in to the handheld and I go to my desktop and it prompts me to update my password and I update my password and I go back to the handheld and try to submit account, it is going to give me that error because I haven’t logged out of the handheld and back in with my new password.

These are common errors to keep your eye on if you ever come across them.

Some productivity reports that come out of the box with Mobile Supply Chain do require crystal reports application server. These reports show some pretty good information. It shows what users are counting which locations, how many units they are counting, the time it’s taken them to count a particular par and then you can also drill down into your operator activity, which will show some more detail about that, which is a good way of seeing, keeping track of … How your users are counting, how frequently they are doing it and how efficient they are at counting their pars.

Stephanie Kowal: For our best practice recommendations. When you are rolling this out or even if you have not utilized it today, making sure you have roles and responsibilities defined. Like Dan was talking about earlier, making sure that there is good communication between IT and the super user administrator and materials. Even when you are doing upgrades and testing needs to happen, it is really important to make sure that you are on the same page and you are communicating and you are testing the process all the way through. If you are going through an acquisition and you are rolling this out to a new company there is going to be a new printers that need to be added and compatibility and often times you will have to back track to remember how it was done three, four years ago when you originally implemented. Making sure that you have a champion in IT as well as Supply Chain is really helpful.

We have seen admin access held in IT as well which isn’t necessarily a bad thing but it can slow down the process when there are new requestors added or new cost center access is needed for security, so it can bog down the IT team when someone in materials can very well handle that and has access for those locations anyways.

You guys have anything else to add to that? No, okay.

Making sure you decide on a labeling solution. Like Dan was mentioning earlier, you can have all these custom labels but maybe you want to have more control over certain areas and make sure you have a standard solution for your pars, for the labeling in those areas.

Dan Farruggio: It sounds like an easy project but the reality is that it takes a lot more time than you would expect especially if you are reorganizing your par areas or inventory locations. If you are doing this by yourself it is a good idea to kind of budget a little bit more time for that than you would originally expect.

Stephanie Kowal: Absolutely. Creating some audit reports to really help make sure you have those setups in sync. Not only the areas that we talked about earlier of adding new items to the pars and making sure they are adding the right vendor, it can also be the administration of users and making sure that you have the right detail on what kind of account unit access they have. I will say that MSCM tables are very very complicated. They … Although they relate back to Lawson IC81, when they go to MSCM they are split in like four or five tables right? You can’t make a quick match to what the par location is because MSCM has named it a numbered sequence. Once you get control over it and have a good understanding you can map everything from there but it’s not straight forward out of the box but it is all written there in MSCM tables. Making sure you have auditing report, maintaining those each day, each week, quarterly depending on what type of information you are looking to get control of.

Keith Wayland: We do have some questions.

Stephanie Kowal: Great. That is where we are at.

Keith Wayland: Awesome. Looks like we have some questions here. Our procurement and distributions are separate and communication between the areas is not good. Our replenishment source records in the IC12 are not in sync with our PO25 priorities and PO13 defaults.

Stephanie Kowal: Yeah, so custom reporting is definitely needed. If you have something like Crystal Reports you could create that logic on your own. Also, working with your IT department that could be done through a SQL statement to check for those priorities. Some of those things could be caught in PO23 and worked through but obviously the goal is to automate that and make sure you are able to have a little bit of control and oversight to those areas.

Jason Kwasnik: Without having Crystal Reports to do it you can do this manually. Just using Microsoft add-ins to pull it in and do look-ups and Access for compares.

Stephanie Kowal: Absolutely. Pulling from the agreement table can be difficult at times but if you have the right criteria there that you can make it work.

Keith Wayland: Sounds like you guys are talking about getting them back in sync. Second half of this question is would you suggest not maintaining replenishment source data in the IC12 at all to better channel items with multiple PO13 and our PO25 records?

Jason Kwasnik: My personal opinion … What I like to do is I only build out IC12s for inventory stock items track and flag yes and then of course you need to have replenishment flags there for your IC140, 141, 142 to pick up properly but I like to see the vendor defaulted from your agreement tables so you know you have an agreement for that item, for that vendor that is active. But everyone has different preferences and there are different ways to do things in Lawson.

Keith Wayland: Another question here, have they really fixed the MSCM productivity reports in version ten, durations were wrong in version nine apparently.

Stephanie Kowal: Not sure about that.

Dan Farruggio: Yeah, haven’t seen anything come across with the durations being wrong but I know there has been a lot of updates and patches for MSCM version ten so I would not be surprised if that has been fixed.

Stephanie Kowal: There are things you can with table data as well to create your own reports to have some more information. I know that those productivity reports are pretty limited. I’ve seen were you go from … All the way from the requisition all the way to the delivery in the area. I am a big advocate for custom reports using something like Crystal or even MS Add-ins to try to paint a better picture.

Any other questions?

Jason Kwasnik: I believe….Alright thank you everybody for joining us. Again if you have any questions feel free to reach out at RPI to Stephanie, Dan, or myself and like Keith had mentioned earlier after editing this will be up on YouTube.

Stephanie Kowal: Great, thanks everyone.

Keith Wayland: Thank you everyone very much for attending. We have another webinar at one o’clock related to Smart Office and one at three o’clock today on DPM. We appreciate your time. Thank you Jason, thank you Dan, thank you Stephanie very much.